Second Approach of the International Conference on Programmable Materials 2022!

We were thrilled with the conference on programmable materials in July 2022!

Due to Covid-19 we had to cancel ProgMatCon 2020 in March 2020.

The conference took place as a hybrid event on July 12-14, 2022 in Berlin at the Fraunhofer-Forum.

The health of all participants was very important to us! That is why we decided to invite the speakers to Berlin and offer a virtual participation to everyone else. It was a priority for us to integrate the on-site speakers and the online-participants and to enable a fruitful discussion between both worlds!

Why attend?

During the event we explored the design space and developed a toolbox of building blocks for programmable materials. We hoped to create relationships between people from relevant scientific subjects, from materials science to chemistry to manufacturing and AI.

Three days full of…

- Top-class plenary talks

- Prof. Dr. Martin van Hecke, FOM Institute AMOLF, Amsterdam

- Prof. Dr. Mark Miodownik, University College, London

- Prof. Dr. Chiara Daraio, California Institute of Technology, California

- Prof. Dr. Aránzazu del Campo, Leibniz-Institut für Neue Materialien, Saarbrücken

- Prof. Dr. Martin van Hecke, FOM Institute AMOLF, Amsterdam

- Five symposia in three parallel sessions with invited talks on the following topics:

Mechanical Metamaterials & Structural and Functional Optimization

Chairs: Heiko Andrä, Chris Eberl

Elastodynamic metamaterials have unusual mechanical properties mainly due to their internal structure, which is often composed of an array of unit cells. Thus, although they are built on the same principle as biological structures, they are less robust and cannot adapt to changing environmental conditions. New manufacturing techniques combined with new multiscale structure optimization methods make it possible to develop and manufacture mechanical metamaterials with variable, locally optimized unit cells. (More information)

Polymers with Sequence Control

Chairs: Stefan Reinicke, Filip du Prez, Alexander Böker

The attempt to realize emerging applications such as sophisticated data storage approaches, adaptive systems/materials or compartmentalized materials for next level catalysis will only be possible when having access to materials showing an enhanced level of functionality. Synthetic protocols to program desired features into polymeric materials thus become increasingly important. (More information)

Shape Memory Polymers & Programmable Property Profiles

Chairs: Thorsten Pretsch, Jean-Marie Raquez, Weimin Huang

The vision of programmable materials is to integrate an “on-demand” function directly into a material. This would allow programmable materials to adapt to any changing environmental conditions in a predetermined manner. Shape memory polymers belong to this emerging class as programmable materials. According to the traditional one-way programming approach, a shape memory polymer is thermomechanically treated to temporarily fix an imposed shape and allow shape recovery after the application of an external stimulus such as heat. The recent approach of programmable materials goes a step further by focusing on programming two-way effects into the same shape memory polymers. (More information)

Design Ideas from Nature

Chairs: Alexander Böker, Peter Fratzl

The future of massively digital industrial applications will require materials that are no longer passive components of active devices, but become themselves operational as carriers of information. Indeed, information stored in smart materials that are responsive and even adaptive does not need to be centrally processed which is both time and energy consuming. This is analogous to natural systems where every activity is distributed over many length scales, from molecule to tissue, organ and the whole organism, and where information is processed both in the periphery and centrally in the brain. (More information)

livMatS symposium on energy harvesting, storage and conversion for Programmable Materials

Chairs: Thomas Speck, Chris Eberl

livMatS develops life-like materials systems inspired by nature. The systems will adapt autonomously to their environment, harvest clean energy from it, and be insensitive to damage or recover from it. The key goal of livMatS is to make the transition from equilibrium or "deeply frozen" metastable, and thus static, materials to dynamic, life-like, non-equilibrium materials systems. The cluster has identified key principles to make this decisive advance towards materials systems. (More information)

- Hybrid event: the speakers gave their talks live in Berlin (of course taking into account the corona regulations)

- Online-Stream and possibility of taking part in the discussion online

- Virtual poster presentation

- Panel discussions

Fostering the paradigm shift in materials research

Global challenges such as sustainable development, climate change, renewable energy, or individual mobility increase the necessity for a much more efficient and sustainable use of our resources.

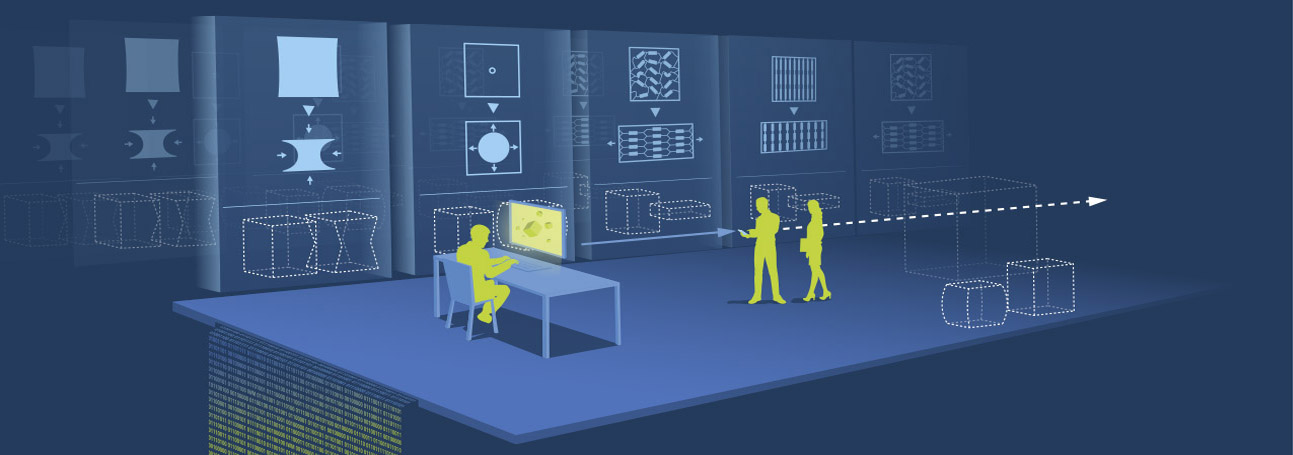

Programmable materials have the potential to initiate a paradigm shift since they can perform system functions through their internal design. This allows for increased functional integration while simultaneously reducing system complexity. Programmable materials are materials whose inner structure is designed and manufactured in such a way that properties and behavior can be controlled and reversibly changed. Furthermore, locally varying functions can be programmed into such materials.

Fully functional programmable materials require a combination of smart materials, mechanical and optical meta materials, the ability to manufacture architectured materials through e.g. additive manufacturing or sheet metal forming. Last but not least a highly interactive, interdisciplinary application design route is necessary to exploit the full potential.

This opens up possibilities for novel application solutions where essential parts of system functionality are provided by the material itself. The programming ability stems from build in logical elements (e.g. if T > 380 K then E = 10 GPa else E = 1 GPa, with E being the Young’s modulus), materials memory (e.g. bistable mechanical or molecular states) and the ability to process functions (e.g. Poisson number as a function of strain in x-direction: ν = f (εx)). The material response can either be triggered externally or the materials can automatically adapt to changing conditions in a predetermined manner.

The application potential for programmable materials is immense: programmable pore sizes enable self-cleaning membrane filters for water treatment systems, materials with programmable heat transfer ensure energy-efficient heat management in machines or buildings, shape morphing materials can change aerodynamics and programmable friction can be used to intelligently control coupling and positioning systems.

Programmable materials have the potential to initiate a paradigm shift in the design and use of materials by replacing technical systems of many components and materials with a single, locally configured one. The key to this is the programmable design of the internal structure.

The first international and interdisciplinary conference on programmable materials aims to facilitate the paradigm shift for materials science described above. It creates the interdisciplinary scientific platform to accelerate the development, production and application of programmable materials. To this end, the conference brings together scientists critical to the success of programmable materials from the disciplines of materials science, mechanics, optimization, process technology and product development and ensures their productive interaction via suitable formats, which is analogous to the integral approach inherent in programmable materials.

The conference is aimed at scientists and engineers who want to advance programmable materials with multidisciplinary contributions, who want to work on powerful tools for their realization, and who want to contribute to the paradigm shift in materials development.

Thematic priorities can be: the simulation of programmed materials, the optimization and programming of material functions, the development of suitable process technology for modular or hybrid production of programmable materials or the validation of programmable materials by demonstrators and prototypes.

With its mix of presented and submitted lectures, poster sessions and workshops, the conference offers interdisciplinary researchers and developers an ideal forum for networking and exchange regarding all relevant aspects of programmable materials.

The International Conference on Programmable Materials is organised by: